Common Hardwood Trees in the United States

Hardwood trees play a significant role in the American landscape, forestry, environment, and the economy. These trees are used as materials for a wide variety of products, from the furniture we put into our homes and buildings to the floors we walk on. They also help minimize America’s carbon footprint when they are used to make hardwood products.

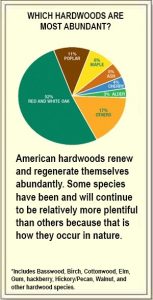

Hundreds of hardwood trees grow in different regions in the United States, each with unique characteristics and uses. Some of North America’s most common hardwood tree species are oaks, maple, hickory, birch, beech, ash, poplar, and cherry.

What Types of Trees are Hardwood Trees?

Most hardwood trees are deciduous and shed their leaves annually. Hardwoods have broad leaves from coniferous trees%20with%20true%20cones) with needles and cones. These trees grow slowly and have tighter grain and higher density, making them ideal for applications requiring strength and durability.

Characteristics of Hardwood Trees

1. Density and Hardness:

- Density: Hardwoods are heavy and strong because their fibers are closely packed.

- Hardness: Hardwood trees are measured by the Janka Hardness Test, which tests their durability and strength.

2. Grain Patterns:

- Hardwood trees have distinct grain patterns that range from straight to wavy. This variety contributes to the aesthetic appeal of hardwood products in furniture, flooring, and decor.

3. Durability and Strength:

- The high density and hardness of hardwood trees are a testament to their long-lasting performance, making them suitable for high-use products.

The Five Most Common Hardwood Trees in the US

North America’s forests grow hundreds of varieties of hardwood in various temperate climates, including the top five most common species: oak, ash, cherry, maple, and poplar.

1. Oak (Red and White Oak)

Red oak and white oak hardwood trees are the most common hardwood trees in the US. Red oak trees grow fast and have bigger pores, giving the hardwood an open grain and a red tone. White oak trees grow slower and have a finer grain, giving a smoother finish and texture. These trees live a long time, sometimes up to hundreds of years.

Uses: Oak wood is known for its versatility and is used as a top material to make:

- Furniture: The strength and beauty of red or white oak make it a popular choice for durable and long-lasting furniture.

- Flooring: Oak’s hardness and resistance to wear and tear make it ideal for high-traffic areas.

- Cabinetry: The distinctive grain characteristics and durability make it a top material for cabinets and kitchens.

- Barrels: Oak is also used in wine and whiskey barrels and can add flavor and texture.

View this post on Instagram

Special Characteristics:

- Red Oak: Our Red Oak at Gutchess Lumber comes from preferred areas of prime timberland within about a 100-mile radius (62 km) of our manufacturing facilities in New York and Pennsylvania. Red Oak is strong, durable, easy to work with, and consistent in color and texture.

- White Oak: Gutchess Lumber White Oak has a light brown heartwood and slightly paler sapwood. It is strong, tough, dense, tight-grained, durable, and beautiful. Our White Oak hardwood is harvested from prime timberland in Pennsylvania, Ohio, and West Virginia. Kiln-dried White Oak is rated as one of the best hardwoods for machining and steam bending.

2. Ash

White Ash grows to 80 feet with a crown that spreads over 50 feet wide. Its lumber turns well and retains such strength that it has been the hardwood choice for many high-end, long-lasting products.

Uses:

- Furniture: Ash is used to make furniture, tool handles, guitar bodies, and lobster traps.

- Flooring: Ash’s wear-and-tear resilience, bright white sapwood, light tan heartwood, and uniform appearance make it a popular choice for flooring in households and buildings.

- Cabinetry: Ash is used for high-quality cabinetry.

- Sports Equipment: It has been the hardwood of choice for making equipment like baseball bats and longbows.

Special Characteristics:

- Smooth Grain: White Ash hardwood features a smooth, consistent grain that takes stain and finishes well.

- Light Color: The wood is typically light in color, ranging from pale yellow to light brown, which makes it versatile to fit different interior designs.

3. Cherry

Black Cherry can grow between 25 feet and 110 feet in height, but the more common height range is between 50 feet and 60 feet. Black Cherry hardwood is malleable, and the wide distribution of the seeds of its fruit by birds makes it abundant in North America.

Uses: Black Cherry wood is used and known for its elegance and versatility in high-quality applications like:

- Furniture: Its rich color and smooth grain make it a great choice for crafting high-end furniture.

- Cabinetry: Black cherry hardwood’s durability and aesthetic are popular for custom cabinetry.

Special Characteristics:

Black Cherry wood features a fine, straight grain with small to medium pores arranged randomly. Its wood growth rings are distinct, and the wood ranges in color from light pink-brown to medium reddish-brown.

View this post on Instagram

View this post on Instagram

4. Maple (Soft and Hard Maple)

Hard and Soft Maple hardwood trees are known for their broad leaves and vibrant fall colors. Soft Maple grows between 30 feet to 100 feet in height in its native area of the Eastern United States and Canada. Hard Maple hardwood species grow from 50 to 80 feet and are abundant throughout the Northeastern United States and Northeastern Canada.

Uses:

- Soft Maple: Used for less formal furniture, cabinetry, and millwork due to its workability and lower cost.

- Hard Maple: Used for high-end furniture, flooring, and musical instruments because of its durability and resistance to wear and tear. It is also used for gym and basketball courts, bowling alleys, bowling pins, rolling pins, and other turnings, skateboard decks, baseball bats, billiard cues, cutting blocks, and a variety of musical instruments.

Special Characteristics:

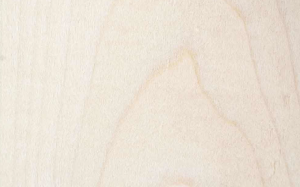

- Soft Maple: Soft Maple has a similar appearance to Hard Maple. Its close-grained sapwood is creamy white, and its heartwood is reddish-brown. The grain of soft Maple Hardwood is often dotted with flecks. Figured grain is less common but highly prized for certain product applications. Gutchess’ Soft Maple lumber is 100% soft-leaf maple.

- Hard Maple: Hard Maple wood features a fine, even-textured grain that can be straight or wavy. Its color ranges from white to cream to reddish or golden-hued.

View this post on Instagram

5. Poplar

Poplar lumber grows between 130 feet and 160 feet tall and has a trunk diameter of 6 feet to 8 feet. It is very low-density and softer, with a Janka Hardness rating of 540 lbf.

Uses:

- Furniture: Poplar wood is used to make inexpensive furniture and cabinetry.

- Plywood: Its lightweight and workability make it a common choice for plywood.

- Millwork: Poplar is used for moldings, trims, and other decorative millwork because of its smooth surface.

Special Characteristics:

Poplar is a light, soft hardwood with a white or light green sapwood cast. Its wood color features a light cream-to-yellow-brown heartwood and pale yellow-to-white sapwood, along with a straight, uniform grain. It is generally free of dark mineral streaks found in southern species.

Gutchess Lumber Poplar lumber is harvested from prime timberland in the northern Appalachian region of Pennsylvania. Poplar hardwood machines easily and takes paints and stains well.

At Gutchess Lumber, we recognize the five most common hardwood trees in the United States: oak, ash, cherry, maple, and poplar. Whether you’re building furniture, flooring, decor, or any hardwood product, these hardwoods offer the strength, durability, and beauty you need to create long-lasting, timeless products.

We offer 11 species of northern hardwoods, where each hardwood species is native to the northeast United States. We oversee tens of thousands of acres of prime timberland and seven facilities across New York and Pennsylvania to produce Gutchess Lumber. Our products come from the best hardwood forests and timberlands in the northeast, several of which we have owned and managed for generations.