Black Cherry lumber comes from one of the most prized hardwood species. Hailing from North America, Cherry wood has its roots in all aspects of life. From fine furniture to musical instruments, this material is well-loved and sought after by artisans and hobbyists alike. Cherry hardwood has earned recognition thanks to its workability, beautiful grain, and magnificent color, so it’s no secret why it’s a staple for several Gutchess customers.

Let’s take a deep dive into Cherry lumber, covering its uses, history, and why it’s such a popular choice for projects big and small.

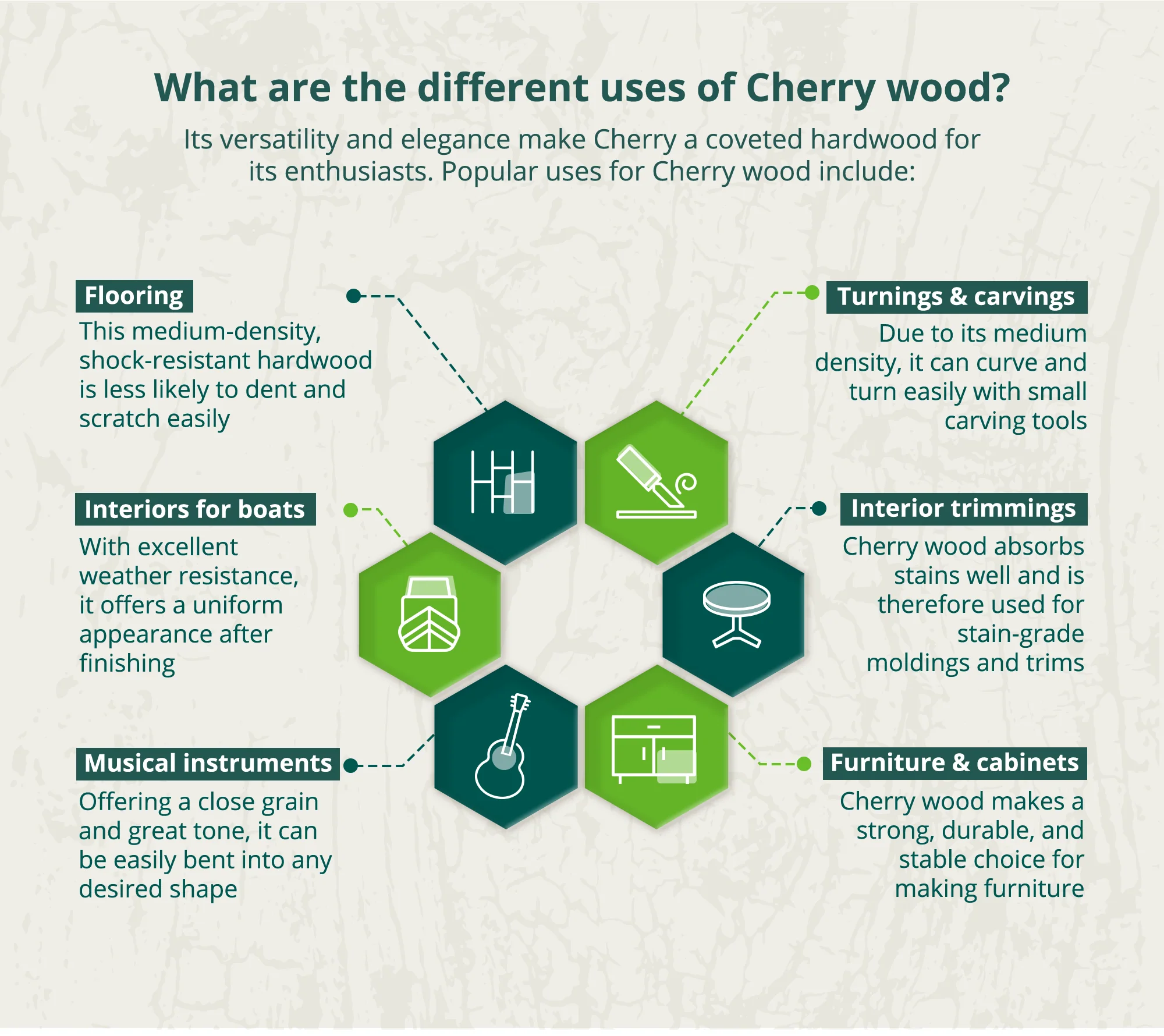

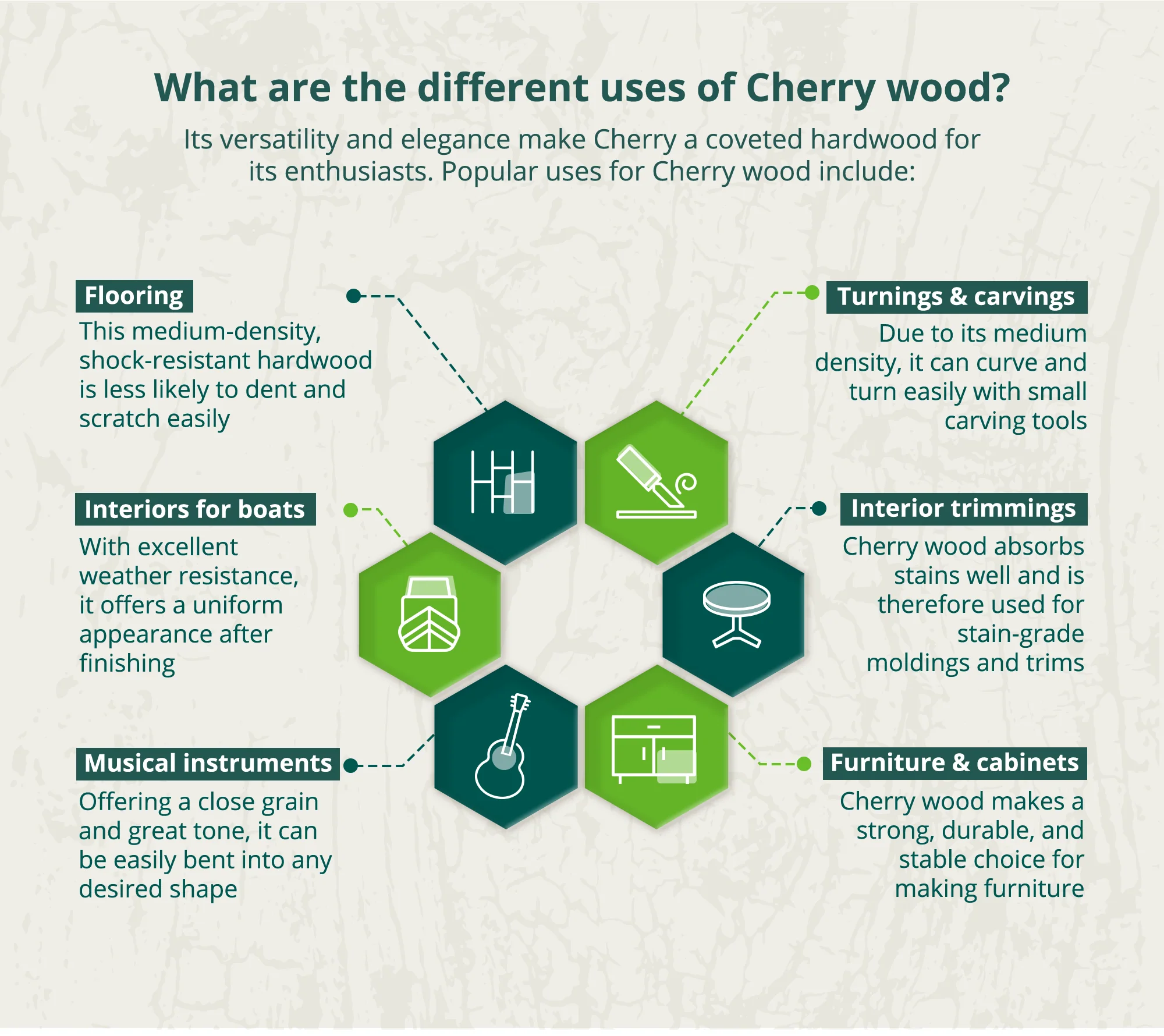

What are the different uses of Cherry wood?

You don’t need to be a lumber expert to know Cherry wood’s beauty. This warm-toned, rich hardwood strikes the perfect balance between strength and flexibility, so it has a variety of uses:

- Musical instruments: is pliable enough to bend without splintering and creates resonant sound in acoustic instruments

- Boat interiors: takes well to weather-proofing and creates beautiful decks

- Carving: isn’t too dense to hand carve for artistic projects

- Furniture and cabinets: offers rich color and superior durability

Over the past few years, bright colors have inspired interior design trends like “dopamine decor,” that feature maximalist furniture and bright colors. With this trend, Cherry wood is poised to surge in popularity as a way to brighten up a space with warm-toned flooring or furniture.

Types of Cherry Wood

It’s important to distinguish between the Cherry wood types because they all come from different regions, from different trees, and have different characteristics. However, true Cherry wood types all fall under the “Prunus” genus. These include:

| Name |

Also Known As |

Region |

Characteristics |

Fun Fact |

| Black Cherry (Prunus serotina) |

- American Cherry

- Rum Cherry

- Wild Cherry

|

Eastern North America |

- Heartwood is a light pinkish-brown color

- Darkens with light exposure

- Sapwood is a pale, yellow color

|

When settlers first came to the United States, colonial furniture builders called this “New England Mahogany” due to its tendency to change color after sunlight exposure.</td |

| Sweet Cherry (Prunus avium) |

|

Europe and Asia |

- Heartwood is a light pinkish-brown color

- Darkens with light exposure

- Sapwood is a pale, yellow color

|

The Sweet Cherry is smaller than the Black Cherry tree with heights that reach between 32 and 65 feet tall. |

| Japanese Flowering Cherry (Prunus serrulata) |

- Oriental Cherry

- Hill Cherry

- East Asian Cherry

- Japanese Cherry

|

China, Korea, and Japan |

- Sapwood is pale pinkish brown to creamy

- Heartwood is brown with gold and green hues

|

This plant is what people often mean when they refer to Cherry trees. |

| Paperback Cherry (Prunus serrula) |

- Birchback Cherry

- Tibetan Cherry

|

Western China |

- Bark peels in layers

- Heartwood has a smooth, mahogany color

|

This tree grows from 20 feet to 30 feet tall, so it’s one of the smaller Cherry trees. |

| Sour Cherry (Prunus cerasus) |

|

Europe and Southwest Asia |

- Typically smaller than other Cherry trees, due to how they’re grown and not valued for lumber.

|

These trees are grown primarily for their fruit. |

Many other tree types fall outside the Prunus genus but are still commonly called Cherry wood. These types aren’t the same species as the true Cherry types we just covered, but they’re categorized as Cherry thanks to their similar properties. They include:

- Brazilian Cherry (Hymenaea courbaril): Otherwise known as Jatoba, this tree earns its name from its resemblance to Black Cherry. The Brazilian Cherry is found in the West Indies, northern South America, and Central America. These trees can grow between 100 feet and 130 feet tall.

- Patagonian Cherry (Guibourtia hymenaeifolia): This tree actually hails from the rose family and is sometimes called the Tiete Rosewood. It’s native to South America, growing between 130 and 165 feet tall. The Patagonian Cherry tree’s wood is dense and hard to work with but its color greatly resembles the Black Cherry tree.

- Barbados Cherry (Malpighia galbra): This tree is known by several names, including Wild Crapemyrtle, Acerola, Manzanita, and more. It can be found in southern Texas, Mexico, Central America, and the Caribbean. The Barbados Cherry got its name because it produces cherry-like fruit, but that’s where the resemblance ends.

- Chilean Cherry (Nothofagus dombeyi): This “Cherry” tree is part of the Beech tree family, though it’s nearly identical to the Black Cherry tree. The Chilean Cherry tree is also called Coigue, hailing from Chile and Argentina.

Cherry Tree Lore

Cherry wood is more than a stylish material used in woodworking and luxury interiors. It’s also part of one of the most well-known American myths that our first president, George Washington, had Cherry wood teeth.

While Washington’s Cherry tree legend has gone through different iterations over the years, the long-standing narrative is that young Washington received a hatchet and cut down a Cherry tree that he shouldn’t have.

When confronted, Washington was honest about the damage. This act solidified his reputation as a virtuous and honest leader. While the legend has been debunked and rebuked, the myth has endured for over 200 years and is an integral part of America’s cultural heritage.

This Cherry Tree myth speaks to the importance of its enduring presence in all aspects of North America — although we can all agree it can stay out of dentistry.

Cherry Wood Traits

The Black Cherry tree (Prunus serotina) is native to North America and some areas of South America. It grows from southeastern Canada, through the eastern United States. In the southern United States, it’s found further west towards Texas, with smaller populations throughout the southwestern United States, Mexico, and Guatemala.

The main commercial areas of Cherry tree growth in the United States include:

- Pennsylvania

- Virginia

- West Virginia

- New York.

The Cherry tree thrives in growing conditions with moist, well-drained soil and full sun to partial shade. The Black Cherry tree is particularly resilient and can grow despite plunging temperatures. Although it’s a medium-sized tree with an average height ranging between 50 and 60 feet, the Black Cherry tree can grow up to 110 feet tall.

It’s found in abundance throughout North America due to its resilience to changing growing conditions and the wide distribution of its seed from various native birds.

Cherry Hardwood Density

The Janka Hardness Scale measures the hardness of domestic wood species, like Cherry wood. This test measures the force required to embed an 11.28mm steel ball halfway into a piece of wood and is expressed in pounds-force (lbf). A higher number rating indicates that a wood species is harder than a species with a lower rating. Although the Janka Hardness Scale is traditionally used to determine whether a wood species is suitable for flooring, it’s a good measure of a wood species’ overall durability.

On the Janka Hardness Scale, the ranking for standard Cherry hardwood is 950 lbf and different types of Cherry wood have similar ratings. Wood species don’t always share similar Janka ratings. For example, Walnut wood’s hardness ranges dramatically depending on where it was sourced.

Thanks to its medium density, Cherry wood has good flexibility and medium shock resistance. This allows it to withstand wear and dents and is why it’s such a popular choice for hardwood furniture.

Cherry Hardwood Wood Grain

Cherry wood features a fine, straight grain except for figured pieces with curly grain patterns, which make it a fine choice for woodworking. As with any wood, there can be defects from pith, mineral deposits, gum pockets, or knots. Cherry hardwood endgrain features small to medium pores with a random arrangement and distinct growth rings.

Are Cherry Trees Hardwood Trees?

Yes, Cherry trees are hardwood trees because they have the main characteristics we use to classify hardwood species.

- Seed type: Hardwoods are angiosperms, which means their seeds develop from flowers into fruit. Cherry trees flower and create fruit.

- Leaf behaviour: Hardwoods are deciduous, which means they lose and regrow their leaves each year. Cherry trees follow this cycle

They differ from softwood trees, whose seeds have none of the protection offered by fruit — they’re simply dropped to the ground to deal with the elements. Softwood tree seeds are needles and cones called gymnosperm, meaning “naked seed.” Almost all softwood trees are evergreen, which means they retain their needles year-round.

Source Quality Cherry Wood from Gutchess Lumber

Source the lumber your customers need to finish their dream projects. Whether you need a dependable lumber manufacturer for your flooring business or a source of ethical materials for local woodworkers, Gutchess Lumber Co., Inc., has the quality Cherry hardwood you need to meet the demand.