How Solid Hardwood Can Improve Your Life

When you think of making upgrades to support your quality of life, you’re probably not thinking of your floors. We might be biased, but it’s true that quality hardwood flooring can improve your life. Don’t believe us yet? We’ll walk you through just how effective this change can be, including its impact on your health and quality of life.

Whether you’re looking to replace an old carpet or damaged floors, Gutchess Lumber Co., Inc. is here to help you source solid hardwood for flooring that lasts for years to come.

Hardwood and Health

If there’s anything we can all agree on, it’s that health should always be a priority. It doesn’t matter if you’re constantly on the go or a homebody — a healthy home environment is essential. You might not know about some common health benefits of working with quality hardwood for your next project:

Physical health benefits

- Less dust and allergens: Hardwood floors don’t trap contaminants the way carpets do.

- No volatile organic compounds (VOCs): Certain flooring types such as carpets or vinyl panels can off gas harmful chemicals called VOCs. Our hardwood is VOC-free.

- Mold-resistance: Hardwood floors are more resistant to mold than other common flooring types.

Mental health benefits

- Low maintenance: Hardwood floors have less upkeep for days when cleaning is a struggle.

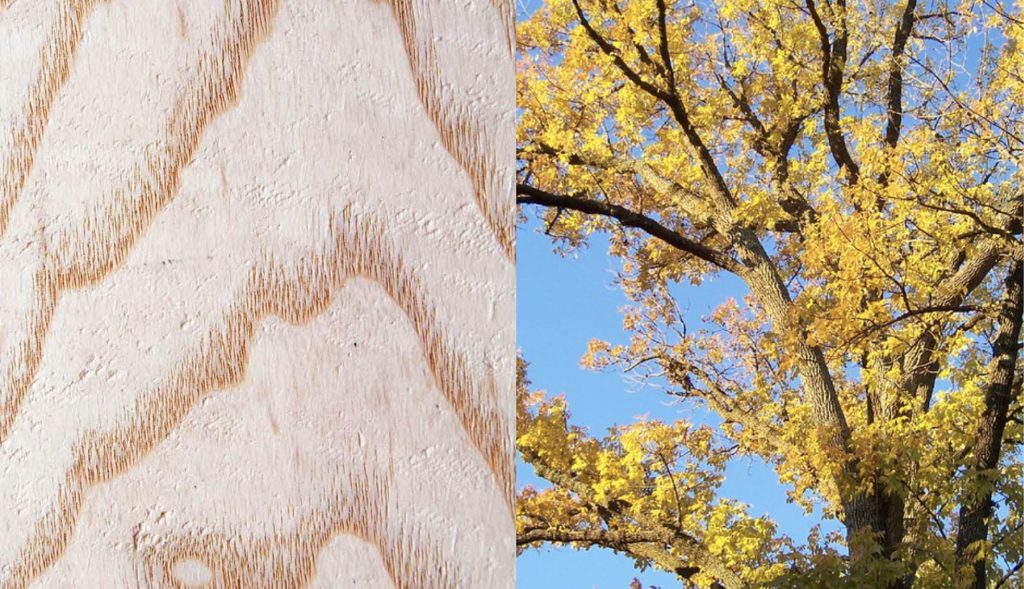

- Grounding environment: Wooden floors remind us of nature, which can boost your mood when stuck inside.

Hardwood and Air Quality

If your home has a lot of dust, you might not realize that the real problem is your carpeting. It’s incredibly difficult to deep clean carpets — and no one wants to vacuum 24/7 to keep up with the allergens. You can remove dust and allergens from solid wood floors with only a quick sweep and mop. This reduces the presence of dust, dander, mites, and even mold spores in your home.

Hardwoods Increase Home Value

Hardwood floors are a desirable feature that can significantly increase home value. New hardwood floors can return 118% of their initial cost if you decide to sell your home.

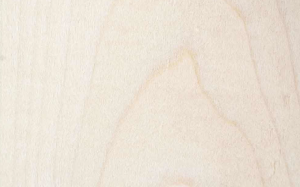

Beyond the health benefits and easy maintenance, solid hardwood is so popular right now because it works well with many popular interior design styles. Whether your home is a mid-century modern getaway, a calming rustic farmhouse, or a biophilic dream cabin, hardwood floors work with any taste.

Environmental Impact

It’s important to think about how your construction and design choices affect the environment. Where you source your materials matters, so find a manufacturer who is transparent about their practices and prioritizes a healthy environment.

At Gutchess, we take our roles as protectors of our forests very seriously. Our environment and sustainability initiatives ensure we source lumber responsibly, consulting with forestry experts and using regenerative harvesting practices.

Hardwood Lumber with a Positive Impact

When it’s time to source quality lumber for your customers, choose a hardwood manufacturer that shares your values. No matter the project, Gutchess provides top-quality service and lumber while working to preserve the natural resources we all rely on. Contact us to learn more about how our premium hardwood can improve your life and impress your customers.

FAQ

What are the benefits of solid hardwood?

Some of the main benefits of using solid hardwood throughout your home include:

- Reduced allergens

- Durability

- Easy maintenance

- Desirable aesthetics

Are hardwood floors healthier?

Hardwood floors are healthier than other floor types, such as carpet, because they’re easier to clean. You can easily sweep, mop, or spot-clean hardwood floors, so they don’t hold on to common allergens like dust and dander. This improves indoor air quality for a healthier home.

Do hardwoods increase home value?

Yes, hardwood floors increase home value. If you want to replace outdated or damaged floors, then choosing solid hardwood can increase your home’s resale value.

What does hardwood have to do with biophilic design?

Hardwood is a common material in biophilic design and architecture. The biophilic style incorporates natural features in buildings or homes. Some common biophilic design choices include:

- Stone and hardwood surfaces

- Large windows for natural light

- Muted, natural color palette

- Water features